Biological Tissue Lyophilization:

Rehydrating Process.

Lyophilization is the process of drying a previously frozen product where the solvent is eliminated by vacuum sublimation. It is commonly used in the food and pharmaceutical industries. It allows convenient storage for long periods, better preservation and sterilization.

The lyophilization when applied to biological tissues as for instance glutaraldehyde treated bovine pericardium will, after re-hydration in saline, show mechanical characteristics similar to the original product. Preliminary studies with membranes of bovine pericardium treated with glutaraldehyde showed that the lyophilization and subsequent re-hydration results in smaller cytotoxicity, smaller amount of chemical residues and improvement of the biocompatibility of the biological tissue.

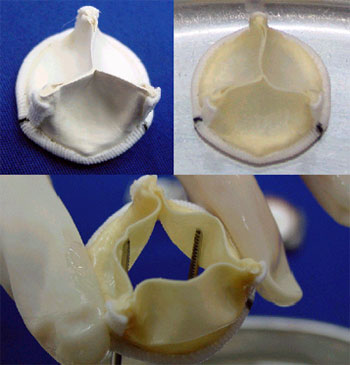

Valve prostheses treated in glutaraldehyde can be washed, lyophilized, packed and sterilized with gamma rays. Once the valve reconstituted by immersion in saline (refer to illustration) it has equivalent performance when compared to the original valve. This same process can be applied to other biological tissue items as for instance porcine valves, patches, ducts etc.

This process of treatment presents the following advantages:

- Simpler storage and handling - Forgoes the use of formaldehyde

- Allows sterilization with gamma rays, superior to formaldehyde.

- Factory pre-washed forgoes pre-implant OR washing

- Lower cytotoxicity. Lower residual aldehydes.

Presently we are performing "in-vivo" tests to evaluate the calcification of the lyophilized-re-hydrated biological tissues.

Bibliography:

MAIZATO, M.J.S., HIGA, O. Z., MATHOR, M. B., CAMILLO, M. A., SPENCER, P. J., PITOMBO, R., ZAVAGLIA, C. A. C., LEIRNER, A.A. Glutaraldehyde treated bovine pericardium: effects of lyophilization on cytotoxicity and residual aldehydes. Artificial Organs, v.27, n.8, p.692-694, 2003.

MAIZATO, M.J.S., SILVA, M.L. HAYASHIDA, S.A., LEIRNER, A.A. Lyophilizes (freeze dried) Bovine Pericardium Valve Prosthesis – An Innovative Preservation Method With Superior Features. ASAIO Journal, p.158, v.50, n.2, 2004.